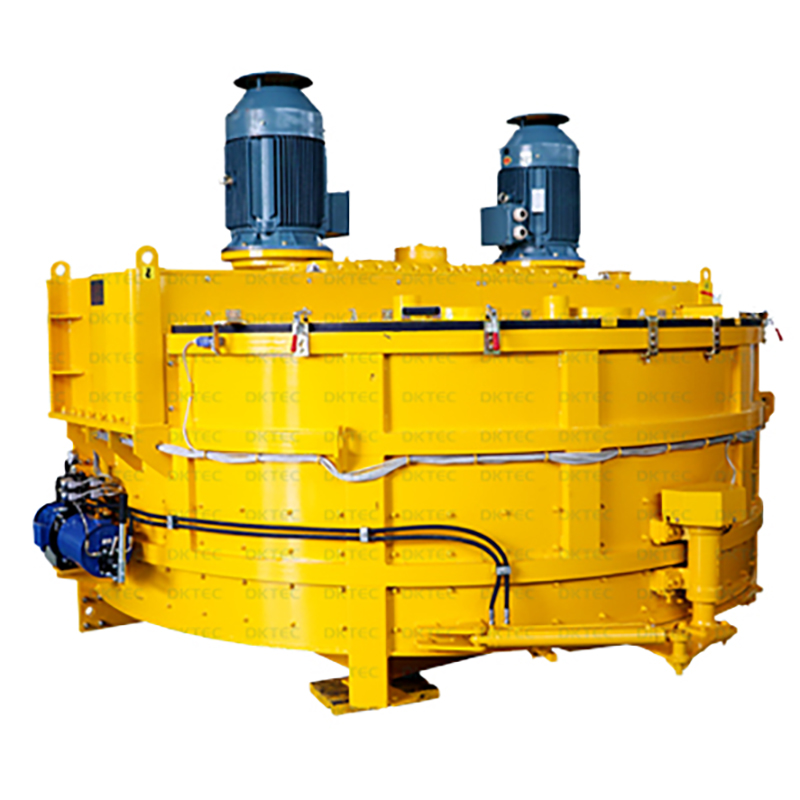

Isitshalo sokuxuba ukhonkolo ochungechungeni lwe-HZS yinto yokukhiqiza enamandla nemishini esebenza kahle kakhulu engakhiqiza izinhlobo ezahlukene zikakhonkolo. Ngokusebenza kahle kokukhiqiza, isetshenziswa kakhulu ekwakhiweni kwezakhiwo ezinkulu naphakathi, ubunjiniyela be-axial yomgwaqo kanye nezimboni ezidingekayo zokukhiqiza imikhiqizo kakhonkolo. Kuyimishini ekahle yokukhiqiza ukhonkolo wezohwebo. Uhlelo lwayo lokuxuba lisebenzisa i-twin shaft mixer ephoqelekile, enokufana okuhle kokuxuba, isikhathi esifushane sokuxuba, impilo ende yokusebenza kokugqoka izingxenye, nokusebenza okulula nokugcinwa. Yamukela ubuchwepheshe bokulawula bamuva njengohlelo lokulinganisa i-elekthronikhi, ukulawula ikhompyutha nokubonisa kwedijithali. Imishini enesisindo se-elekthronikhi ifakwe amadivayisi we-buffer nemisebenzi yesinxephezelo ezenzakalelayo, ngokunemba okuphezulu kwesilinganiso. Uhlelo lokuphakelwa kwesihlabathi nohlalu lwamukela ibhande elikhulu le-herringbone lokondla futhi linemigwaqo eseceleni. Kuyinketho efanelekile yenani elikhulu lamayunithi wokwakha ukukhiqiza ukhonkolo omuhle kakhulu.

I-DKTEC ingahlangabezana kalula nezidingo zamakhasimende ngezitshalo zayo ezihlanganisiwe zokuxuba ukhonkolo ezinamakhono ahlukahlukene nokucaciswa.

Inezinhlobonhlobo zezinto ezihlanganisiwe zokubhaka ukhonkolo, namandla wokukhiqiza we-mixer asukela ku-60m³ / h kuye ku-180m³ / h. Futhi singenza ngezifiso izixazululo ngokuya ngezidingo zamakhasimende, i-imeyili yethu: sales@dongkunchina.com

Ngaphezu kwalokho, esitshalweni esifanayo sokuxuba ukhonkolo onabahlanganisi ababili, umthamo wokukhiqiza ungafinyelela kuma-cubic metres ayi-240 / ihora kanye nama-cubic metres ayi-360 ngehora.

| Into | Iyunithi | HZS25 | |

| Ukukhiqiza theory | m³ / h | 25 | |

| Ukukhishwa kwesixubi | m³ | 0.5 | |

| Uhlobo lokuphakela | Ukuphakamisa i-hopper | ||

| Imodeli ye-Batcher | m³ | I-PLD800 | |

| I-batcher (ivolumu ngomgqomo ngamunye) | m³ | 3 | |

| I-batcher (inani lemigqomo) | pc | 4 | |

| Amandla esihlanganisi | kw | 18.5 | |

| Amandla okuphakamisa | kw | 5.5 | |

| Ukukhishwa kokuphakama | m | 1.5 / 2.7 / 3.8 | |

|

UMax unesisindo

|

Ukuhlanganiswa | kg | 1500 ± 2% |

| Impahla yempuphu | kg | 300 ± 1% | |

| Impompo yamanzi | kg | ± 1% | |

| Futha lengetiwe | kg | ± 1% | |

| Into | Iyunithi | HZS35 | |

| Ukukhiqiza theory | m³ / h | 35 | |

| Ukukhishwa kwesixubi | m³ | 0.5 | |

| Uhlobo lokuphakela | Ukuphakamisa i-hopper | ||

| Imodeli ye-Batcher | m³ | I-PLD800 | |

| I-batcher (ivolumu ngomgqomo ngamunye) | m³ | 3 | |

| I-batcher (inani lemigqomo) | pc | 4 | |

| Amandla esihlanganisi | kw | 30 | |

| Amandla okuphakamisa | kw | 7.5 | |

| Ukukhishwa kokuphakama | m | 1.5 / 2.7 / 3.8 | |

|

UMax unesisindo

|

Ukuhlanganiswa | kg | 2000 ± 2% |

| Impahla yempuphu | kg | 500 ± 1% | |

| Impompo yamanzi | kg | ± 1% | |

| Futha lengetiwe | kg | ± 1% | |

| Into | Iyunithi | HZS60 | |

| Ukukhiqiza theory |

m³ / h |

60 | |

| Ukukhishwa kwesixubi |

m³ |

1 | |

| Uhlobo lokuphakela |

|

Ukondla kweBelt | |

| Imodeli ye-Batcher |

m³ |

PLD2400Q-Ⅲ | |

| I-batcher (ivolumu ngomgqomo ngamunye) |

m³ |

10 | |

| I-batcher (inani lemigqomo) |

pc |

4 | |

| Amandla aphelele |

kw |

92 | |

| amandla wokuxuba |

kw |

2x22 | |

| Kuthambekele amandla ibhande elihambayo |

kw |

11 | |

| Ukukhishwa kokuphakama |

m |

4.1 | |

| Isisindo sonke |

kg |

38000 | |

| Ubukhulu (L × W × H) |

m |

38x18x20.7 | |

| UMax enesisindo sokunemba | Ukuhlanganiswa |

kg |

1200 ± 2% |

| Usimende |

kg |

800 ± 1% | |

| Impahla yempuphu |

kg |

500 ± 1% | |

| Amanzi |

kg |

250 ± 1% | |

| Izithasiselo |

kg |

20 ± 1% | |

| Into | Iyunithi | HZS90 | |

| Ukukhiqiza theory |

m³ / h |

90 |

|

| Ukukhishwa kwesixubi |

m³ |

1.5 |

|

| Uhlobo lokuphakela |

|

|

|

| Imodeli ye-Batcher |

m³ |

PLD2400Q-Ⅲ |

|

| I-batcher (ivolumu ngomgqomo ngamunye) |

m³ |

10 |

|

| I-batcher (inani lemigqomo) |

pc |

4 |

|

| Amandla aphelele |

kw |

130 |

|

| amandla wokuxuba |

kw |

2 × 30 |

|

| Kuthambekele amandla ibhande elihambayo |

kw |

22 |

|

| Ukukhishwa kokuphakama |

m |

4.1 |

|

| Isisindo sonke |

kg |

45000 |

|

| Ubukhulu (L × W × H) |

m |

39.5 × 18 × 20.7 |

|

| UMax enesisindo sokunemba |

Ukuhlanganiswa |

kg |

2400 ± 2% |

| Usimende |

kg |

800 ± 1% |

|

| Impahla yempuphu |

kg |

600 ± 1% |

|

| Amanzi |

kg |

350 ± 1% |

|

| Izithasiselo |

kg |

20 ± 1% |

|

| Into | Iyunithi | HZS120 | |

| Ukukhiqiza theory |

m³ / h |

120 |

|

| Ukukhishwa kwesixubi |

m³ |

2 |

|

| Uhlobo lokuphakela |

|

|

|

| Imodeli ye-Batcher |

m³ |

PLD3200Q-IV |

|

| I-batcher (ivolumu ngomgqomo ngamunye) |

m³ |

14 |

|

| I-batcher (inani lemigqomo) |

pc |

4 |

|

| Amandla aphelele |

kw |

180 |

|

| amandla wokuxuba |

kw |

2x37 |

|

| Kuthambekele amandla ibhande elihambayo |

kw |

30 |

|

| Ukukhishwa kokuphakama |

m |

4.1 |

|

| Isisindo sonke |

kg |

70000 |

|

| Ubukhulu (L × W × H) |

m |

38 × 26 × 22 |

|

| UMax enesisindo sokunemba | Ukuhlanganiswa |

kg |

3600 ± 2% |

| Usimende |

kg |

1200 ± 1 |

|

| Impahla yempuphu |

kg |

1200 ± 1 |

|

| Amanzi |

kg |

600 ± 1% |

|

| Izithasiselo |

kg |

50 ± 1% |

|

| Into | Iyunithi | HZS180 | |

| Ukukhiqiza theory |

m³ / h |

180 |

|

| Ukukhishwa kwesixubi |

m³ |

3 |

|

| Uhlobo lokuphakela |

|

|

|

| Imodeli ye-Batcher |

m³ |

Ingxenye #: PLD4800Q-IVV |

|

| I-batcher (ivolumu ngomgqomo ngamunye) |

m³ |

18 |

|

| I-batcher (inani lemigqomo) |

pc |

4 |

|

| Amandla aphelele |

kw |

275 |

|

| amandla wokuxuba |

kw |

2x55 |

|

| Kuthambekele amandla ibhande elihambayo |

kw |

45 |

|

| Ukukhishwa kokuphakama |

m |

4.1 |

|

| Isisindo sonke |

kg |

90000 |

|

| Ubukhulu (L × W × H) |

m |

45 × 20 × 22 |

|

| UMax enesisindo sokunemba | Ukuhlanganiswa |

kg |

4800 ± 2% |

| Usimende |

kg |

1600 ± 1% |

|

| Impahla yempuphu |

kg |

1600 ± 1% |

|

| Amanzi |

kg |

800 ± 1% |

|

| Izithasiselo |

kg |

100 ± 1% |

|

HZS uchungechunge ukhonkolo kuhlangana isitshalo yakhiwa Ukuxuba uhlelo, Material batching uhlelo, Isisindo uhlelo futhi uhlelo kagesi. Ifanele izindawo zokwakha ezinkulu nezincane, izitshalo zomkhiqizo kakhonkolo we precast nezitshalo zokukhiqiza.

Ukuxuba uhlelo

I-twin shaft mixer ekhonkolo inamandla okuxuba aqinile, ikhwalithi yokuxuba iyunifomu nokukhiqiza okuphezulu. Inomphumela omuhle wokuxubana kokhonkolo nobulukhuni obomile, ubulukhuni obomile, ipulasitiki nobukhulu obuhlukahlukene. Uhlelo lokuthambisa kanye ne-main shaft drive system konke kungeniswe kusuka kwiphakheji yokuqala, futhi indlela yokuvula umnyango wokubacindezela ingalungisa ukuvulwa komnyango wokukhipha njengoba kudingeka. Umphini wokuxuba womshini wokuxuba oyinhloko usebenzisa ubuchwepheshe bokulwa nokubambelela ukuvimbela ngempumelelo ukuhlangana kukasimende kushaft. I-shaft end seal yamukela isakhiwo sokufaka uphawu esiyingqayizivele sokuvikela ukuvuza kodaka nokuqinisekisa ukusebenza okuqhubekayo nokwesikhathi eside kwalo lonke uhlelo lokuxuba. Uhlelo lokuhlanza lisebenzisa ingcindezi yokumpompa amanzi ngokucindezela okuzenzakalelayo nokulawula okwenziwa ngesandla, Izimbobo ezidayisa amanzi zitholakala ngqo ngaphezu kwesiphungulu sokuxuba, esithuthukisa ukusebenza kahle kokuxuba, sandisa inkungu yamanzi, sinciphise ukungcola kothuli futhi sisuse ngempumelelo ukuhlangana kukasimende. Ifanele ukwakhiwa okukhulu, izinkampani zikakhonkolo wokuhweba, njll.

Isistimu Yokuqoqa Okuhlanganisiwe

Khetha umshini wokubhaka; indlela yokondla ihlelwe ngendlela "yomkhiqizo" futhi yondliwe ngudlulisi webhande; isebenzisa izindlela ezimbili zesisindo somuntu ngamunye nesisindo sokuqoqeka; isisindo se-elekthronikhi, ukulawula i-PLC, ukubonisa kwedijithali; t inesisindo esinembile, ukucacisa okuphezulu kwe-batching, isivinini esisheshayo, umsebenzi wokulawula oqinile, ukusebenza okulula, njll.

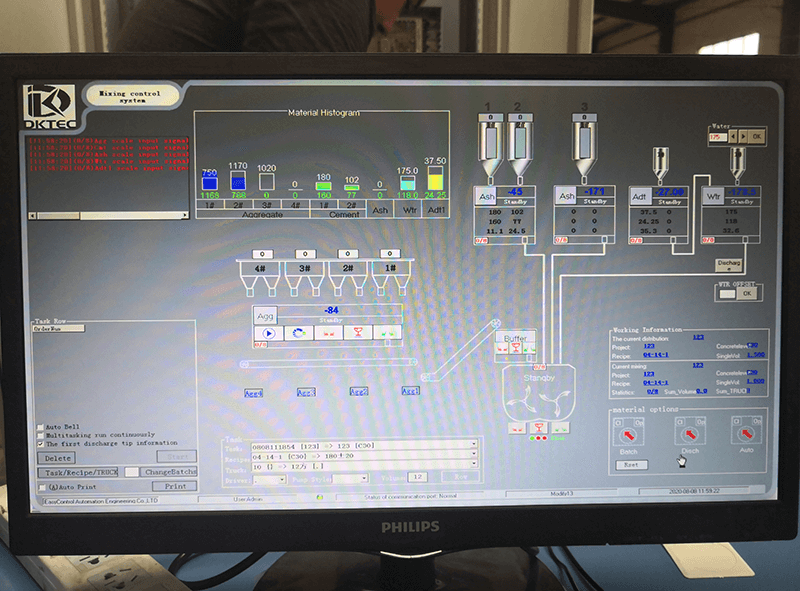

Uhlelo Lokulawula

Faka isicelo sezinto ezingenisiwe, ukusebenza okuthembekile; ukuphathwa okukude, amalungelo wabasebenzisi angabelwa, afeze izinqubo eziyisisekelo zokuphatha iphrojekthi; ukulawula okuhlakaniphile, ukulawula okuzenzakalelayo, ukulawula okwenziwa ngesandla; ngokugcina isilinganiso, ukunxeshezelwa kokudonsa okuzenzakalelayo, ukukala ngokweqile, ukulungiswa kwe-alamu okungaphansi kwesilinganiso; Imishini inemisebenzi efana nokuqapha ukusebenza, ukugcinwa kwamafu wedatha, ukuphrinta, njll.

Isistimu Yesisindo

Impuphu, amanzi, nezithasiselo konke kukalwa ngezikali zikagesi; ukunemba kwe-batching kuphezulu futhi ukulinganisa kunembile; usimende, umlotha we-fly, ne-hopper yokulinganisa amanzi isekelwa ohlakeni ngamasethi amathathu wezinzwa, anesakhiwo esizinzile nokuthembeka okuphezulu; i-metering hopper yokwengeza ilinganiswa ngenzwa eyodwa yokuphakamisa

Isitshalo ngasinye sokuxuba senzelwe amakhasimende!

Intengo yesitshalo ngasinye sokubhaka iyahlukahluka ngenxa yamalungiselelo ahlukile!

Uma udinga ukwazi imininingwane eningiliziwe yamanani esiteshi sokuxuba esincane, ungashayela ngqo inombolo yethu yokuthengisa: 0086-571-88128581

Ngokuya kokucushwa okudingayo, sizonikeza ikhotheshini enembile futhi sikuvumele uthole ulwazi oludingayo ngesikhathi esifushane!

Ukugcinwa komxube wokhonkolo

1.Qiniseka ukuthi umshini nendawo ezungezile ihlanzekile.

2.Sula izinto ezinqwabelene ku-hopper ngesikhathi sokwenza inzwa ibuyele ku-zero ngokujwayelekile.

3.Hlola ukuthi uwoyela wokuthambisa endaweni ngayinye yokugcoba unele yini, futhi i-lubricator ohlelweni lomoya kufanele igcine uwoyela owanele.

4.Hlola ukuthi ama-motors nezinto zikagesi zishiswe ngokweqile noma umsindo ongajwayelekile, ukuthi ngabe inkomba ijwayelekile yini nokuthi uhlelo lwesiginali lumi kahle yini.

5.Hlola futhi ulungise isilinda, ivemvane valve kanye ne-solenoid valve njalo ukwenza ukuvulwa nokuvalwa kuhlangabezane nezidingo.

6.Hlola uhlelo ngalunye njalo, futhi ubhekane nalo ngesikhathi uma kukhona ukuvuza kothuli, ukuvuza kwegesi, ukuvuza kukawoyela nokuvuza kukagesi.

7.Isihlanganisi nokukhipha i-hopper kufanele kuhlanzwe njalo emahoreni amane ukuvimbela ukhonkolo oyinsalela ekuhlanganiseni nasekuvimbeleni ukusebenza okujwayelekile.

I-8 .Konke ukushintshwa kufanele kudedele amanzi angaphakathi we-air compressor, ithangi lokugcina umoya nesihlungi, futhi aqede ukungasebenzi kahle okwenzeka ngesikhathi sokusebenza.

I-9.Iveluvemvane, i-mixer, i-solenoid valve, isihlungi somoya nedivayisi yenkungu kagesi zigcinwa ngokuya ngemiyalo efanele.