Isitshalo sokubhaka ukhonkolo ongumahamba nendlwana ngumklamo ofakwe i-trailer. Ukuhanjiswa okuqoqayo, isixubeki sikakhonkolo, amasistimu enesisindo, isikulufa sokuhambisa kanye nesilo samente kudidiyelwe kakhulu kuyunithi efakwe yi-trailer, okuyisakhiwo esihlanganisiwe Ukuze kuhlangatshezwane nokusebenza kahle, ukusebenza kahle nokuhlangana, isitshalo sokubhaka ukhonkolo weselula si- ixhunywe ngokuphelele kusuka efektri, okunciphisa isikhathi sokufakwa nokusebenza kwecala lesitshalo sokukhonkolo esikhonkolo.

| Into | Iyunithi | MHZS60 | |

| Ukukhiqiza theory | m³ / h | 60 | |

| Ukukhishwa kwesixubi | m³ | 1.0 | |

| Uhlobo lokuphakela | Ukondla kweBelt | ||

| Imodeli ye-Batcher | PLD1200-Ⅲ | ||

| I-Batcher (inani lemgqomo) | m³ | 12X2 | |

| amandla wokuxuba | kw | 22X2 | |

| Amandla okuphakamisa | kw | 7.5X2 | |

| Ukukhishwa kokuphakama | m | 3.9 | |

| Isisindo esikhulu nesinembile | Ukuhlanganiswa | kg | 2500 ± 2% |

| Impahla yempuphu | kg | 600 ± 1% | |

| Amanzi | kg | 250 ± 1% | |

| Izithasiselo | kg | 20 ± 1% | |

| Into | Iyunithi | MHZS75 | |

| Ukukhiqiza theory | m³ / h | 75 | |

| Ukukhishwa kwesixubi | m³ | 1.5 | |

| Uhlobo lokuphakela | Ukondla kweBelt | ||

| Imodeli ye-Batcher | PLD2400-Ⅲ | ||

| I-Batcher (inani lemgqomo) | m³ | 15x2 | |

| amandla wokuxuba | kw | 30x2 | |

| Amandla okuphakamisa | kw | 11x2 | |

| Ukukhishwa kokuphakama | m | 3.8 | |

| Isisindo esikhulu nesinembile | Ukuhlanganiswa | kg | 3000 ± 2% |

| Impahla yempuphu | kg | 800 ± 1% | |

| Amanzi | kg | 350 ± 1% | |

| Izithasiselo | kg | 20 ± 1% | |

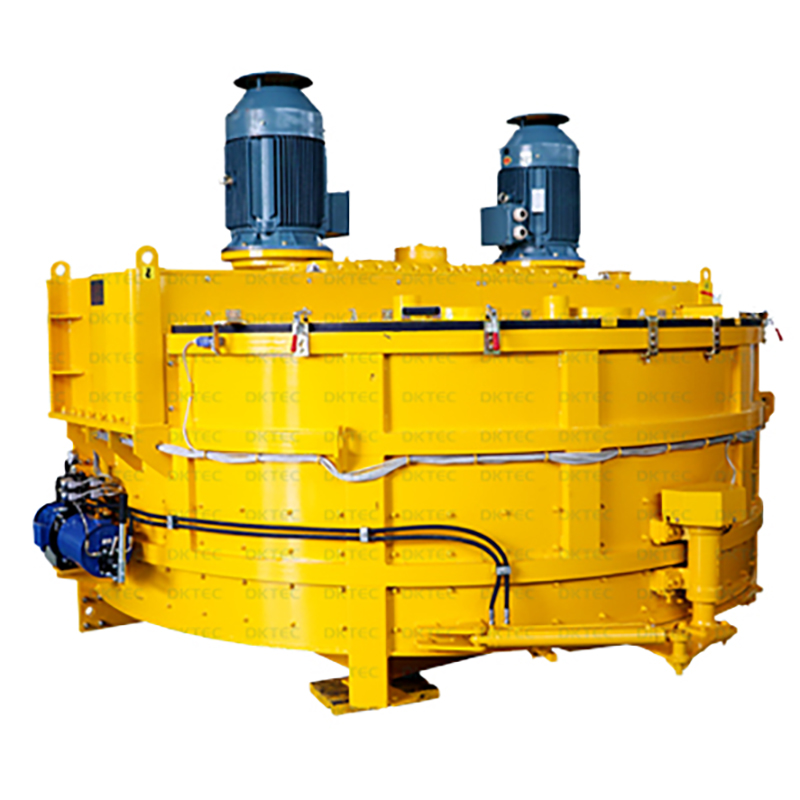

1. Ukwakhiwa kwesakhiwo okuhlanganisiwe, kugxilwe kakhulu ezingxenyeni zesiteshi sokuxubana kuyunithi eyodwa ye-trailer;

2.Imodi yokusebenza yomuntu, umsebenzi ozinzile nonokwethenjelwa, ukusebenza okuzinzile ezindaweni ezahlukahlukene ezinzima;

3. I-Twin-shaft mixer ekhishelwe ngaphandle (i-mixer yamaplanethi nayo ingasetshenziswa), engasebenza ngokuqhubekayo, ixube ngokulinganayo, futhi ixube ngokuqinile nangokushesha; ingaqedwa ngesikhathi esifushane. Kukhonkolo onzima, ukhonkolo onzima, ipulasitiki nobukhulu obuhlukahlukene bukakhonkolo, ingaxubeka kahle.

4. Isitshalo sonke singasheshe sithuthwe sisiwe esakhiweni futhi sihlanganiswe esizeni ngefomu eligcwele eligcwele;

5. Uku-pre-commissioning kuqediwe ngaphambi kokulethwa, futhi ukwakhiwa kungenziwa ngaphandle kokuthunyelwa;

Ukucushwa okuyinkimbinkimbi, izinga eliphakeme lokuzenzekelayo, ukunyakaza okuguquguqukayo futhi okulula, ukusebenza okulula nokuzinzile.

Isakhiwo esikhulu sesitshalo sekhonkolo sokubhaka ukhonkolo sihlukaniswe izingxenye ezintathu: uhlelo lokulawula, ungqimba lokuxuba kanye nongqimba olunesisindo sokubhaka.

Ingxenyekazi yesendlalelo sokuxuba yenziwe ngohlaka lohlaka lwensimbi olunesigaxa esikhulu esimise okwe-I kabili, esisindayo futhi esinokuqina okungcono nokumunca ukushaqeka kunokwakheka okujwayelekile.Ulwelwesi lokuxuba nongqimba oludlulisayo lwakha umzimba oqinile, ohlanganisiwe ngesisekelo, okunciphisa ngempumelelo ukudlidliza okuvela kumxube wokhonkolo; ukwesekwa kwamukela imilenze engunxande, engeyona elula nje ngesakhiwo, kepha futhi evulekile esikhaleni.

Igumbi lokulawula lizungezwe ngamawindi, axhumene nomzimba omkhulu wesitshalo sokuxuba ukhonkolo, futhi angakhiwa ukuthi abe nobude obufanayo nongqimba lokuxuba. Ipulatifomu yokuhamba yesendlalelo sokuxuba yenziwe ngensimbi yensimbi, evumelana nokubuka okufika ngesikhathi kokukhiqizwa nokukhishwa komgcini wokuxuba. Ngaphambi kokushiya ifektri, uhlelo lokulawula luyalingiswa futhi lulungiswe kabi futhi luxhunywe izixhumi zezindiza, ezinciphisa umsebenzi wokufaka esizeni kanye namathuba okwehluleka. Akunasidingo sokuqaqa kabusha futhi uxhume izintambo lapho udlulisa imishini.

Kukhona ama-hopper amabili anesisindo (usimende, umlotha we-fly), amanzi owodwa anesisindo se-hopper, i-admixture emibili enesisindo se-hopper kanye ne-hop ye-pre-storage eyodwa ehlelwe kusendlalelo esinesisindo. Zonke izisindo zisebenzisa izinzwa zokucacisa okuphezulu, ukufakwa okulula, ukulungiswa okulula nokusetshenziswa okuthembekile. I-outlet ye-powder enesisindo se-hopper isebenzisa i-valve yomoya we-butterfly elawulwa ngokuzenzakalela, uxhumano oluthambile nokuvalwa okugcwele kuyamukelwa ku-ithelet nasendaweni. I-admixture enesisindo se-hopper ihlelwe ngaphezulu kwe-metering hopper yamanzi, futhi indawo esetshenziswayo isebenzisa i-valve yensimbi engagqwali ukukhipha ukwaziswa.

Ingqikithi ngumthamo onqwabelene noma isilinganiso esisodwa sesikali se-elekthronikhi. Usimende, amanzi nezithasiselo kunesisindo sama-hopper ngesilinganiso esinembile, ukulawula okuphakathi kwe-PLC, nokusebenza okulula. Isamba sihanjiswa futhi sondliwe ngamabhande. Noma kungukulinganisa kokuhlanganiswa, impuphu noma amanzi, isivinini sokusampula sidlula izikhathi eziyi-120 ngomzuzwana, futhi ukunemba nokwethembeka kwesilinganiso kuqinisekiswa yizinzwa ezinemba kakhulu. Ukulawulwa okumaphakathi kwe-PLC, kungaqhutshwa ngokuzenzakalela noma ngesandla. Lapho ikhompyutha yezimboni noma i-PLC yehluleka ukulawula ukukhiqizwa okujwayelekile kwesitshalo sokuxuba, izinkinobho zokusebenza mathupha nazo zingasetshenziswa ukufeza ukusebenza okwenziwa ngesandla ukugwema ukuphazamiseka kokukhiqiza. Umsebenzi ulula futhi kulula ukuwazi. Isibonisi sephaneli esinamandla singaqonda ngokusobala isimo sokusebenza kwengxenye ngayinye, futhi singagcina siphrinte idatha yombiko (wokuloba wokuphrinta, i-quadruplicate), enikeza lula kakhulu ukuphathwa kohlelo lokukhiqiza. Inama-system wokuqapha amabili wokuqapha kwesikhathi sangempela. Isimo sokukhiqiza.

Izinto eziyinhloko kagesi zesixubi, isikulufa somshini, inzwa yokulinganisa, izinto zokulawula umoya nohlelo lokulawula konke kungumkhiqizo ongenisiwe, onganciphisi kuphela kuphela ukwehluleka kwemishini, kepha futhi kuthuthukisa ukunemba kokulinganisa kwemishini

▶ Yiziphi izingxenye zesitshalo sokuxuba esingumahamba nendlwana?

1 I-Mixer chassis:

I-cantilevered mixer chassis yenjini enkulu, equkethe iphini logandaganda nomlenze wokupaka iloli; Isilinganiso sesilinganiso se-mixer, usimende namanzi, ukuxubana kwaseshashalazini.Set around the patrol table, railing nokunye.

Igumbi lokulawula:

Igumbi lokulawula lingezansi kwekhrisimesi yokuxuba, kanti isitshalo sokuxuba silawulwa ngokuzenzakalela ngaphakathi ngaphakathi. Igumbi lokulawula lisebenza njengendawo yokusekela engaphambili yesitshalo sonke lapho sisebenza. Lapho kudluliswa futhi kuthuthwa, igumbi lokulawula liyabekwa futhi ligcinwe emgodini webakaki; yonke imigqa yokulawula ayidingi ukuqaqwa.

Isilinganiso sokuhlanganiswa:

Lolu hlelo lutholakala ekugcineni kwangemuva kwesiteshi sokuxuba esihambayo, ingxenye engenhla iyisihlanganisi (isihlabathi, itshe) sokugcina isitoreji, isitolo se-hopper singahlukaniswa sibe yi-2 noma i-4, bese simisa ibhodi eliphezulu ukukhulisa umthamo wokugcina, womoya ngokulandelana vula ukusebenza komnyango, isilinganiso sokulinganisa sezinhlobonhlobo zesilinganiso sokuqongelela izinto.Iphansi ifakwe ibhuloho elihamba ngemuva nemilenze yohlaka yokusebenza.

4 izingxenye Peripheral:

Okwe-samente silo kanye ne-screw conveyor, izingxenye zomngcele ziyizinto ezibalulekile kungakhathalekile ukuthi umsebenzi noma ukuthuthwa, ngakho-ke zingathuthwa zihlukaniswe zizonke ngaphandle kokuqaqa.

▶ Yiziphi izici eziyinhloko zesitshalo sokubhaka ukhonkolo oselula?

Isici esikhulu ukuthi singahamba ngokuphelele.Okwamanje, isiteshi esixubekayo sokuxuba ukhonkolo sihlukaniswe kakhulu ngohlobo lokudonswa nohlobo lokuhudula, uhlobo lokudonswa kohlobo lwe-traction luqukethe ibhuloho eliphelele langaphambili nangasemuva; I-chassis edonswayo ine-ekseli yangemuva kuphela , nengaphambili layo lifakwe ebhulohweni lesihlalo sogandaganda.